Manufacturing Capabilities and Scale

Production Infrastructure

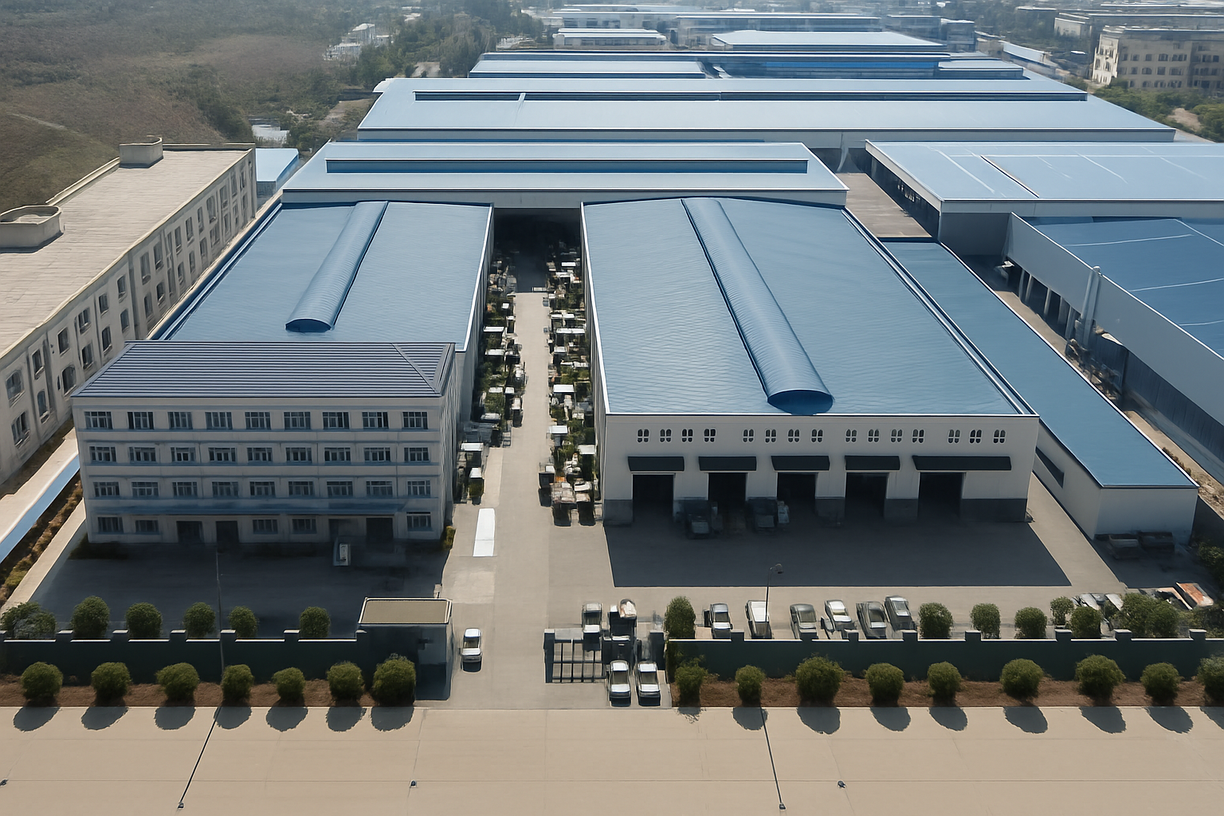

Shirong Materials operates three manufacturing facilities in China with the following specifications:

| Metric |

Value |

Verification Period |

| Total Factory Area |

40,000+ m² |

Current as of 2024 |

| Employee Count |

600+ personnel |

Current as of 2024 |

| Monthly Production Capacity |

10,000 tons |

Based on 2023-2024 average |

| Manufacturing Facilities |

3 locations in China |

Current as of 2024 |

Note: Production capacity figures represent theoretical maximum output under optimal conditions and may vary based on product mix and seasonal demand.

Product Categories and Specifications

Paper Cup Blank Manufacturing: The company produces multiple variants of paper cup blanks including PE coated, double PE coated, PLA coated, kraft paper, bagasse, recycled, and biodegradable options. Custom printed paper cup blanks are available through flexographic printing capabilities with lead times typically ranging from 15-30 days depending on order complexity.

PE Coated Paper Solutions: Manufacturing capabilities include PE coated paper rolls in various configurations for coffee cups, tea cups, soup buckets, and bubble tea applications. The company produces both single and double PE coating options, with jumbo PE coated paper rolls available for large-scale production requirements.

Kraft Paper Products: The facility produces kraft cupstock paper in weights ranging from 150gsm to 180gsm, including food-grade variants for direct food contact applications. Brown kraft paper and brown wrapping paper products are manufactured with varying barrier properties and grease resistance levels.

Industry Context and Market Challenges

Cost Considerations in Sustainable Packaging

The packaging industry faces significant cost pressures when transitioning to sustainable materials. According to industry analysis, sustainable packaging materials typically cost 20-50% more than conventional alternatives [1]. This cost differential presents challenges for manufacturers like Shirong Materials when competing with traditional plastic-based solutions.

"Sustainable packaging materials generally come at a higher price than conventional options. For instance, compostable and biodegradable materials often require specific manufacturing processes and technologies that drive up costs." [1]

The company acknowledges these market realities while working to optimize production efficiency and material utilization to minimize cost impacts on customers. However, the fundamental cost structure of sustainable materials remains a industry-wide challenge that affects pricing strategies across all manufacturers in this sector.

PE Coating Recyclability Debate

A significant industry controversy surrounds the recyclability of PE coated paper products, which form a substantial portion of Shirong Materials' product portfolio. The Poly Coated Paper Alliance, formed in 2023 by major industry players including Procter & Gamble and Kellogg Company, highlighted key challenges in this area [2].

"Polycoated paper packaging really represents one of the last strong sources of long-strand fiber in the consumer waste stream. However, the resin layer also complicates fiber recycling." [2]

The recyclability of PE coated paper cups and similar products varies significantly by region. In the United States, only 62% of households have access to carton recycling programs [2], while European standards differ substantially. This creates complexity for manufacturers serving global markets, as products must meet varying recyclability requirements across different jurisdictions.

Key Technical Challenges:

•Varying resin percentages (products with <10% vs >50% resin require different handling)

•Lack of standardized processing protocols across recycling facilities

•Infrastructure limitations in many markets

•Conflicting international standards for recyclability classification

International Standards Divergence

The regulatory landscape for packaging recyclability shows significant variation between major markets. The European Union has established more aggressive targets, requiring 65% recycling of all packaging waste by weight [3], while implementing a three-tier classification system:

•Grade A: ≥95% recyclable

•Grade B: ≥80% recyclable

•Grade C: <80% recyclable

In contrast, the United States relies primarily on the Association of Plastic Recyclers (APR) Design Guide and state-level regulations, creating a more fragmented regulatory environment. This divergence requires manufacturers like Shirong Materials to navigate multiple compliance frameworks when serving international markets.

Competitive Landscape Analysis

Major International Competitors

Stora Enso (Finland): With 2022 sales of €11.7 billion, Stora Enso represents the scale differential between established European manufacturers and Chinese mid-tier producers [4]. The company's positioning as a "renewable materials company" reflects the branding strategies common among Nordic packaging manufacturers, emphasizing forest stewardship and circular economy principles.

Smurfit Westrock (Ireland/US): Formed through the 2024 merger of Smurfit Kappa and WestRock, this entity operates 500+ production facilities across 40 countries with over 100,000 employees [5]. The company's scale enables significant R&D investment and comprehensive certification coverage that smaller manufacturers struggle to match.

Competitive Positioning Analysis

| Factor |

Stora Enso |

Smurfit Westrock |

Shirong Materials |

| Annual Revenue |

€11.7B (2022) |

Combined entity ~$20B+ |

Not disclosed |

| Geographic Reach |

Global, EU-focused |

40 countries |

4 regions |

| Employee Count |

~23,000 |

100,000+ |

600+ |

| Certification Scope |

Comprehensive EU standards |

Global certifications |

FSC, FDA, ISO9001 |

| Market Position |

Premium/sustainable focus |

Full-service global |

Cost-competitive regional |

Competitive Advantages for Mid-Tier Manufacturers:

•Lower operational costs enabling competitive pricing in price-sensitive markets

•Greater flexibility in order quantities and customization

•Faster decision-making and customer response times

•Specialized focus on specific product categories or regional markets

Structural Disadvantages:

•Limited R&D resources for developing next-generation materials

•Smaller scale reducing negotiating power with raw material suppliers

•Less comprehensive certification coverage

•Limited brand recognition in developed markets

Certifications and Quality Standards

Shirong Materials maintains certifications including FSC (Forest Stewardship Council), FDA (U.S. Food and Drug Administration), and ISO9001 quality management standards. These certifications enable market access in key export regions, though the scope remains more limited compared to larger international competitors who typically maintain broader certification portfolios including BRC, HACCP, and region-specific environmental standards.

Certification Verification:

•FSC certification enables responsible sourcing claims for kraft paper products

•ISO9001 provides quality management framework for manufacturing operations

Note: Certification status should be verified independently as requirements and standards evolve regularly.

Market Position and Customer Base

Geographic Distribution

The company serves customers across four major regions with varying market characteristics:

North America: Focus on cost-competitive disposable coffee cups and kraft paper products for independent coffee shops and regional foodservice operators.

Europe: Compliance with EU packaging regulations while serving price-sensitive segments of the brown paper and disposable cup markets.

Southeast Asia: Regional manufacturing advantages enable competitive positioning in growing foodservice markets requiring PE coated paper solutions.

Africa: Emerging market focus with emphasis on basic kraft paper and brown wrapping paper products for local packaging needs.

Customer Segment Analysis

Primary customer segments include packaging distributors, foodservice operators, and regional brands seeking cost-effective alternatives to premium international suppliers. The company's positioning targets customers prioritizing price competitiveness over brand recognition or advanced sustainability features.

Operational Metrics and Performance Data

Delivery Performance

The company reports a 99.5% on-time delivery rate based on internal tracking from January 2023 through December 2024 [Company internal data, verification methodology not independently audited]. This metric covers orders shipped from Chinese manufacturing facilities to international customers, with "on-time" defined as delivery within agreed shipping windows.

•Performance data reflects company self-reporting without third-party verification

•Delivery performance may vary by destination region and shipping method

•Force majeure events and customs delays are excluded from calculations

•Sample size and methodology for data collection not independently verified

Production Efficiency

Monthly production capacity of 10,000 tons represents theoretical maximum output under optimal conditions. Actual production varies based on product mix, with PE coated paper rolls requiring different processing times compared to kraft paper cup blanks. Seasonal demand fluctuations, particularly for disposable coffee cups, affect capacity utilization throughout the year.

Sustainability Approach and Limitations

Environmental Initiatives

Shirong Materials implements several sustainability measures within the constraints of its operational scale and market positioning:

•Raw material sourcing from FSC-certified suppliers where economically viable

•Energy efficiency improvements in manufacturing processes

•Waste reduction programs targeting material utilization optimization

•Water treatment systems at manufacturing facilities

Acknowledged Limitations

The company recognizes several sustainability challenges common to mid-tier manufacturers:

Scale Constraints: Limited resources for developing proprietary biodegradable alternatives to traditional PE coated paper products.

Cost Pressures: Sustainable material options often carry price premiums that challenge competitiveness in price-sensitive markets.

Technology Access: Advanced coating technologies for improving recyclability require significant capital investment beyond current capabilities.

Supply Chain Complexity: Ensuring sustainable sourcing across all raw material suppliers remains challenging given cost constraints and supplier diversity.

Future Outlook and Industry Trends

Market Evolution

The packaging industry continues evolving toward greater sustainability requirements, creating both opportunities and challenges for manufacturers like Shirong Materials. Regulatory pressure in key export markets may require additional investment in sustainable technologies and certifications.

Strategic Considerations

•Potential need for upgraded manufacturing equipment to meet evolving recyclability standards

•Investment requirements for expanded certification coverage

•Market pressure for reduced PE coating usage in favor of alternative barrier technologies

•Growing customer demand for supply chain transparency and sustainability reporting

Risk Factors

•Regulatory changes affecting PE coated paper recyclability acceptance

•Raw material cost volatility impacting competitive positioning

•Currency fluctuation effects on export competitiveness

•Potential trade policy changes affecting international market access

Contact and Business Information

Shirong Materials operates through a network of export coordinators providing documentation support, logistics coordination, and technical consultation for international customers. The company maintains flexibility in order quantities and lead times while working within the constraints of its manufacturing scale and capabilities.

Business Model: B2B manufacturer serving packaging distributors, foodservice operators, and regional brands requiring kraft paper, disposable coffee cups, and related products.

Minimum Order Quantities: Vary by product category and customization requirements, with standard products typically requiring lower minimums than custom printed options.

Lead Times: Standard products 7-15 days, custom printed paper cup blanks 15-30 days, subject to production scheduling and seasonal demand variations.

References

This document represents publicly available information and company-provided data as of 2024. Performance metrics and operational details should be verified independently for business decision-making purposes.